Motorcycle clutches connect the engine and the gearbox or separate them. When you change your speed, the clutch is engaged and communicates the situation to the engine and wheels. When disengaging, there is no longer any transmission between the engine and the wheels. Too much stress, the clutch wears out over time. This requires maintenance, periodic checks and replacements. These procedures not followed and the lack of control of your motorcycle would lead to unexpected breakdowns such as clutch slippage. The main reasons for this slippage are:

- wear and tearclutch,

- wear of the flywheel,

- incorrect adjustment of the clutch lever,

- uncontrolled starting.

Clutch slip

The clutch device has three operating phases:

- the engaged position

This is the most stable step that facilitates the transmission of power supplied by the clutch because no control is active.

- the disengaged position

It is the stopping of the transmission or the neutral point. The motor operates without activating the wheels.

- the transient phase of sliding

This is the slip point where the gradual re-establishment of power transmission takes place during engagement.

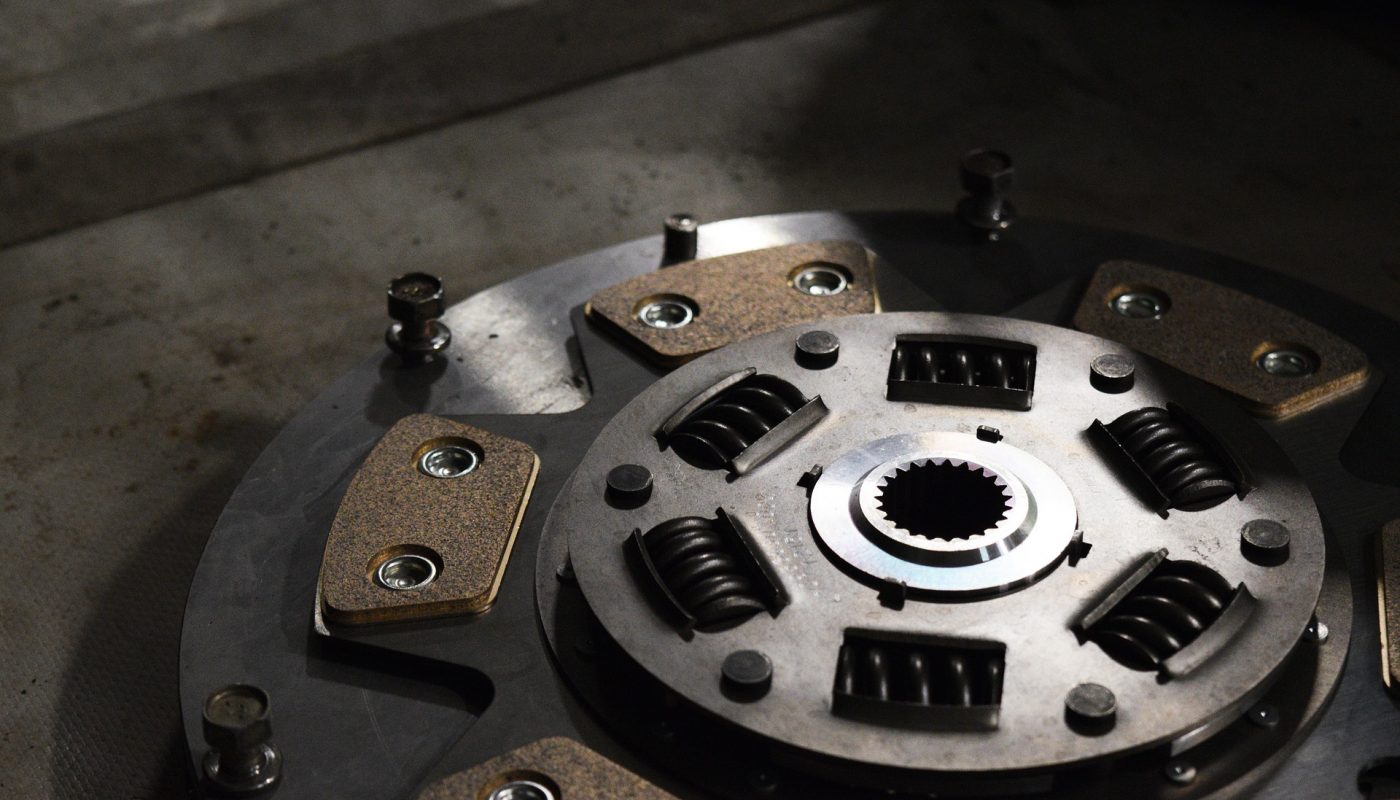

During this third phase, the engine and the clutch device do not have the same speed. Hence the phenomenon of sliding between the discs. This causes heat dissipation which is just energy. Even if you cannot escape it, the constraint is the limitation to this solicitation in time. This limit causes degradation of the disks used at hill start-up.

Clutch wear

The signs of scooter skating to detect wear on this item are:

- difficult gear change

This is the easiest to determine. There is resistance when you change your speed. You get the impression that the clutch assembly feels stiff when handling your motorcycle.

- increasing engine revolutions without speed boost

Normally the engine revs and speed match. When you find that it is not, your motorcycle's clutch is deformed.

- the softness and deformation of the clutch housing

This is often seen during strong acceleration or jolts.

- the clicks of the shock absorber when starting

When you maintain your scooter, checks of certain parts lead to identifying the wear points:

- the disks

The calculated deformation of the steel discs is not tolerable (after consulting the manual) and the discs are bluish, the replacement of these discs is essential. The wear of the discs also results in the wear of the clutch housings and internal drives.

- Springs

You observe that they are cowardly.

Frequent maintenance or a new clutch

To be far-sighted,

- Revise your scooter according to the manufacturer's instructions.

- Talk to your mechanic about the condition of your clutch at each visit.

- Maintain the clutch assembly by reading your scooter manual.

In general, the maintenance of your scooter is detailed as follows:

- Prepare the tools.

- Cover the ground and drain the oil.

- Loosen the fixing sleeves.

- Remove the cover, center nut and screws.

- Disassemble the clutch by removing the compression springs, clamping plate, steel discs and friction discs from the clutch.

- Measure the length of the clutch springs.

- Compare their length with the wear limit mentioned in your manual. Inconsistency means replacement.

- Check the condition of the discs using a dressing plate. Deformation also indicates replacement.

- Disassemble the clutch housing by loosening the central nut.

- Hold the trainer with a special tool.

- Smooth the small gaps on the sides of the insert guides with a file.

- Check the condition of the clutch housing damper.

- Assemble the clutch devices.

- Adjust the clearance by replacing the cover and screws.

- Adjust the clutch lever.

Otherwise the renewal of all the clutch devices is imperative as soon as the symptoms appear by consulting the related frequency in the manual of your scooter.

Wear of the flywheel

A flywheel is a part of the engine, having the shape of a cast iron disc that connects the engine and the clutch. The flywheel is involved in clutching and starting.

After 200 km, the flywheel is declared worn. The springs constituting the structure of the flywheel are technically at the origin of the slipping of the clutch of your scooter.

The wear of an engine flywheel can be synonymous with deformation of the starter pinion. The rotation of the flywheel depends on that of the starter pinion.

This deformation is quickly identified by:

- vibrations to the engine and the clutch pedal,

- difficulties in changing gears which are associated with jerks when the engine is under revs,

- clutch buzzing.

Checks or corrections on the flywheel

Two solutions are available to you:

- Check your motorbike.

The mechanic will either replace the part or correct the surface, which will take place in the factory.

- Only change the starter gear if it is the only bent part.

Note that the flywheel has a lifespan of up to 200 km.

- for failures occurring before 100km, repair or replacement is recommended. Ask the manufacturer of your scooter what to do!

- for those arriving at 200km, trust your mechanic! It will change clutch kit connected to the flywheel.

Improper adjustment of the clutch lever system

Each time you start, you actuate this lever which is located to the left of the handlebars.

This bad setting is checked if:

- the outer engine rod is under stress.

Normally, the linkage oscillation is light by hand. Otherwise, it is tight and the clutch cannot engage properly.

- the cable has slack

- the cable is seized

The free sliding of the cable in its sheath is normal. The movement of the lever is due to the manipulation of its part visible to the engine.

- failure to respect the crossing points studied by the manufacturer.

This disrespect can cause a fall or damage the wiring harness.

Modifications or replacement of this system

Solutions still exist for each symptom:

- In the event that the rod is constrained, the wheel on the lever must be tightened by a few mm until the rod is released. If this is not sufficient, adjust the motor housing nuts by softening the cable.

- For cable slack, reducing it is recommended. If this is still not enough, keep it halfway through the stroke and adjust it to the motor housing.

- When the cable is seized, replacement is the only option.

- Regarding the passage points, the cable must be put back in place by photographing the passage of the cable beforehand, by unscrewing the bottom nuts and by adjusting the slots of the knobs to the lever.

It is also essential to lubricate the clutch lever regularly and sufficiently so as not to cause the clutch to slip.

The uncontrolled start

At this time, learning to slip the clutch is compulsory for obtaining a driver's license. The evaluation is done in slow course events keeping a very low speed and driving through urban streets.

Starting, which is not mastered, is common for beginners. Instead of quickly letting go of the clutch at the start of its swing, it holds it too long. When the skater effect occurs, the novice driver releases the clutch lever too soon. Finally, the motorcycle stalls.

A starting technique to check

To solve this problem, it is necessary to reach as quickly as possible the point of skidding obtained by releasing the clutch lever in a normal way in order to control it then with a calculated time: 5s or 5m.

Among other things, when the skater effect occurs, keep this skating point by rolling only in a straight line and without accelerating if possible. The moment you technically master this point, synchronize the effort with the throttle.

Be aware that your clutch lever does not continuously put pressure on the clutch. Its role is to identify the point of slip by bringing the discs closer to the clutch.

Successive clutch changes

Some enthusiasts make various adjustments to the clutch and thrust springs of their motorcycle. They want to improve the performance of their motorcycle without respecting the maintenance deadlines recommended by the scooter manufacturer. They then buy parts that do not match the model. These modifications also generate modifications in the assembly diagram of the elements of the clutch. It's a bad idea ! Which would result in:

- clutch slip a short distance even if you accelerate, then

- the gradual cold and hot slowing of your scooter. So the carburetor is damaged and the spark plug melts.

Timely changes

To avoid this kind of situation, change your clutch kit according to the recommendation of your scooter manufacturer. Usually it's every two years!

Symptoms are also precursors to modify a clutch:

- maintaining the clutch lever excessively,

- the foul smell of used used oil,

- the black color of the used oil,

- the presence of filings in the used oil,

- the stalling of the motorcycle when you are in first gear or you stop,

- the difficult search for a neutral point,

First equip yourself with a complete tool kit:

- the tool module (1/4 ″ sockets and ratchet),

- the mechanical gloves,

- le 6l drain pan,

- le motorcycle lift.

In order to fix this system:

- wash your scooter.

- lay him on a motorcycle lift.

- drain your motorcycle and use a workshop stand.

- lock your fuel tap if it exists.

- separate the cable and the clutch housing.

- remove the clutch cover.

- access the tray and take it apart.

- remove the smooth and trimmed discs.

- fool the new ones discs in the engine oil.

- replace the discs.

- reassemble the discs right side up, the pressure plate and the housing.

- tighten the screws crosswise and in torque.

- introduce oil in the crankcase.

- change your oil filter.

- check the oil level.

- check the controls (the condition of the cable and the clutch lever; bleeding the clutch fluid for the hydraulic one).

Further information & advice on the scooter clutch

There are times when your scooter does not engage. So what are the reasons?